Two of the 20 or so Jupiters and 60 or more other Jowetts: a couple of Bradfords can be seen in the background.

Proud Jupiter owners the world over cannot resist leaving their car's bonnet lifted.

The Jowett Jupiter is a hand-built car.

At the JCC rally May 24th 1998 Edmund Nankivell met a number of former Jowett employees, who had been apprenticed at the Jowett factory early in the 1950s and who had worked on the Jupiter. They recalled making component parts for Jupiter such as the grilles, the windscreens, the seat frames, and numerous other components they pointed out to Edmund. These piece-parts started life as sheet steel or sheet brass, etc, requisitioned from their stores. The sheets were guillotined to size, nibbled to shape, and then formed by hand over wood or steel formers or jigs. In fact, the Jowett Jupiter Sports Car was built entirely by hand by skilled craftsmen.

|

Jowett Car Club Rally, May 24th 1998. Two of the 20 or so Jupiters and 60 or more other Jowetts: a couple of Bradfords can be seen in the background. Proud Jupiter owners the world over cannot resist leaving their car's bonnet lifted. |

Some, indeed many, of the Jupiter's components, even quite humble ones like the water pump spindle rear support, required such a high degree of skill to make that it looks as if the Jupiter was seen as a training device for tinsmiths and sheeties.

The tubular chassis began life as lengths of tubing and little pieces of sheet steel. The tubes were cut to the 40 or so pieces required, the ends shaped. The 40 or so sheet steel components were cut, shaped and drilled. Astonishingly every individual piece had a part number and a name! The chassis was progressively welded up on a rotatable jig until finished. It then went to Inspection, then to the bonderising and stove-enamelling shops, before joining a heap of frames outside in the open, waiting until needed by the Production line.

The tubular chassis steel is a high-chromium / high-molybdenum alloy that is significantly lighter than nornal steel, and doe not rust. Being rust-free is so handy for restoration projects!

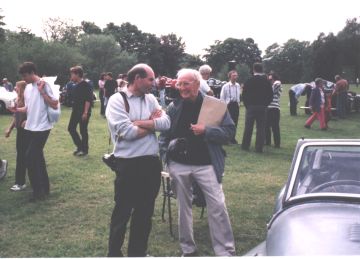

| In this picture, taken at the 1998 JCC rally as above, Peter Holden (with

camera) talks to Harry "Digger" Metcalf (with buff envelope). Peter was the JCC Spares Officer. "Digger" was an apprentice at Jowett Cars in the early 1950s, and made Jupiter components. To the right, wearing braces, is Dennis Sparrow, who ran a Jowett workshop in London. |

|

Skilled panel-beaters worked tirelessly with rolling machine and mallet to form the aluminium body panels, which then needed to be invisibly welded into larger panels.

Truly the Jupiter was totally hand-made at Bradford, Yorkshire, just like the pre-war vehicles. By contrast, the Javelin saloon car bodies, and Bradford van bodies were brought into Jowett as complete bodies already trimmed and painted (from the Briggs Car Bodies factory) with just the mechanicals to be added at the Jowett factory.

Some changes to the Jupiter during its production life:

| Chassis No. | Completion Date | Modifications, developements |

| 1 and 5 | March 1950 | The first 2 Jupiters were prototypes, but the most visible distinguishing feature apart from the strakes was the windscreen which had all corners rounded. Brakes were hydraulic at front, mechanical at rear. |

| 1, 5, 17 to 21 | March - November 1950 | Strakes on the sides of the bodies were retained only for these Jupiters |

| 41 to 45, 51 to 55 | Dec 1950 - Jan 1951 | Strakes deleted. Otherwise the bodywork was just like chassis 17 - 21 |

| 56 | 5 January 1951 | This was the first Jupiter with full hydraulic brakes and larger brake friction area. |

| 165 approx | June 1951 | Louvres added to bonnet for improved cooling whilst car is stationary. |

| 439 approx | October/November 1951 | Petrol pump (suction type) relocated from firewall near engine to down on chassis (pressure type) to overcome vapour lock. |

| 504 approx | December 1951 | Shorter engine-oil filler pipe. For some cars, this component fouled the centre grille. |

| 940 | October 1952 | Mk 1a available with externally opening boot. 8 gallon fuel tank (it is 11

gallons on the Mk1). Metal instrument panel and door tops (wood on the Mk1). Tubular

crossbracing to support the door hinges introduced. The Mk 1 continued to available for a time, some with the cross-bracing and metal door tops. |

| 935 | 23 June 1953 | The last Mk 1 Jupiter shipped out of the factory. |

| 1033 | 4 November 1954 | The last Mk1a Jupiter shipped - which is the last Jupiter that Jowett built (and of course their last car). |

Note: Gaps in early Jupiter chassis numbering (chassis 6 to 16, 22 to 40 etc in column 1 above) were rolling chassis shipped to coachbuilders to construct their own bespoke bodies. Later gaps in chassis numbering represent genuine gaps, hence the total build was not 1033 Jupiters of all types, as the chassis number of the last Jupiter suggests, but 827 standard Factory-built Jupiters and 75 rolling chassis. Moreover, chassis 2 was the Factory "exhibition" chassis, and it was finally built into the last complete Jupiter: chassis 1033.

This gives us a total factory build of 899 Jupiters including special bodies. To this one could add the three R1 sports racing Jupiters and the three R4 Jupiters.

||Quirky Jupiter photos||A Jupiter travels to Hyeres||

More Links...

Here below you can determine links to the outside world. But gluttons for yet more chit-chat about Jupiters might wish to jump to the Magazine overflow page.

The Jowett car factory was sited at the village of Idle, within the city of Bradford in West Yorkshire, England. Bradford is "vibrant - diverse - full of surprises".

There is an online Classic Car auction website www.classicmotorauction.com. Your car can be auctioned with Classic

Car Auctions whilst being secure in your possession.

The need to travel miles to

view a car that is often not as expected is eliminated; the company ensures that

the vehicles offered are as described

and have safeguards in the unlikely event

that the vehicle is not as expected.

There is a jowett.com website. It wasoriginally devoted to an American clothing mill of the name

Jowett Garment Factory based in El Monte,

California.

It is now the JOWETT GROUP, with one company in the USA, three companies in Mexico, and a related company in Taiwan

They claim to be a major supplier of sports apparel.